AI Build

Partners and Resellers

Jobs & Career

3D Printing

3D Scanning

Software Training

Post Processing

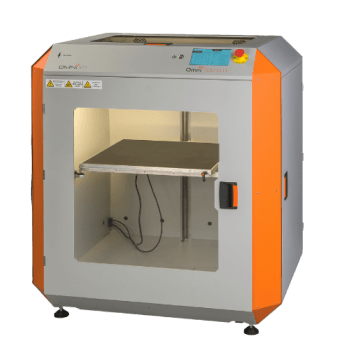

Omni LITE

Machine for demanding customers with quick and easy operation with industrial standards.

Key Features:

- Build volume 460 x 460 x 600 mm

- 2 extruders with filament presence sensor

- Heated bed up to 130 deg C

- nozzle diameters 0.4, 0.6, and 0.8mm

Guaranteed Lower Price

✔ Brand New

✔ Installation Services

✔ User Training

✔ Warranty Services

✔ Online Support

Product Overview

Omni LITE

You can print large objects or multiple smaller models at once. The printer can be managed through a dedicated website, so you can easily start printing and control the process remotely. The possibility of remotely building and managing a printer set.

Omni3D Web Control

Remote management and preview of 3D printer operation are features that significantly change the quality of work with the printer and increase the possibilities of everyday machine management.

Omni3D Platform Autoleveling System

Printers working in FDM technology print an object on a so-called work platform, i.e. a flat, horizontal plane or, in other words, a table. Correctly leveling the 3D printer table is one of the first things that must be done before printing, and it is also a necessary step in obtaining a successful printout.

Omni3D Filament Flow Control

One of such systems is Omni3D Filament Flow Control, which watches over the quality, but also over our budget, time and nerves, because it is able to detect the lack of filament, its jams and all undesirable activities that may happen to the filament during printing.

Why FDIND?

We aim to satisfy our clients by providing them the best product based on their requirements.

Who We Are

The leading national supplier of Additive Manufacturing solutions. Years of expertise in all related systems.

Customer Services

Our goal is that you as a customer should feel secure and happy with our offerings

Quality First

One stop for selected, tested and powerful 3D printers, 3D scanners, software, filament, resin and accessories at an affordable price